DE12 Diesel Used Engine Blocks For Excavator DX500 Water Cooling

Specification

| Car name: Engine cylinder block |

| Model Number: DE12 |

| Cylinder stroke: 123 |

| Cylinder diameter: 155 |

| Application: Excavator |

| valve: 12 valve |

| Cooling: Water cooling |

| Injection: Direct |

| Work form: Turbo |

Description

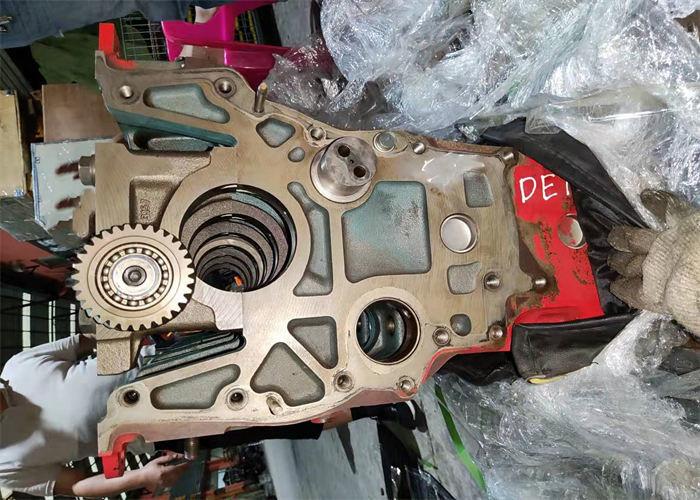

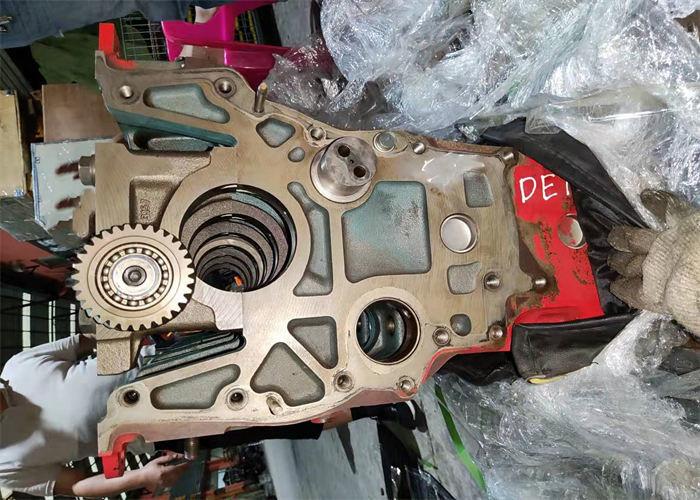

Pre-cast features and add-on parts

Depending on the applied casting process, additional components

and/or functions such as water pump housings and flanges can be

incorporated into the main casting. Furthermore, bore holes for

bolting and oil channels can be directly cast.

While pre-casting of bolt bores is a standard technique today, the

casting of very tiny features such as oil channels is now possible

with advanced casting processes, e.g. the core package casting or

the lost foam process.

Using high-precision sand cores, a variety of parts and flanges can

be incorporated into a single casting. Issues like dimensional

stability and accuracy of positioning have to be addressed. But

higher costs for using an advanced casting process are easily

compensated by savings in the area of machining and assembly.

Cast-in inserts

Engine blocks which are subject to very high loads, e.g. in case of

direct injection diesel engines, can be reinforced in critical

areas by cast-in inserts of higher strength materials. But cast-in

inserts are often used also to provide specific functions.

Cast iron inserts for bearings

Aluminium casting alloys are generally not suitable for bearing

applications for two reasons:Their wear resistance is not

sufficient to withstand the sliding wear of the crankshaft.

The higher thermal expansion (compared to grey iron and steel) may

lead to a not acceptable increase of the gap between the crankshaft

and the bearing (which is strongly influencing the required oil

pressure and increases the noise level).

For these reasons, cast iron inserts are often pressed into the

component after machining, but they can also be directly cast-in

resulting in reduced costs for machining and handling.

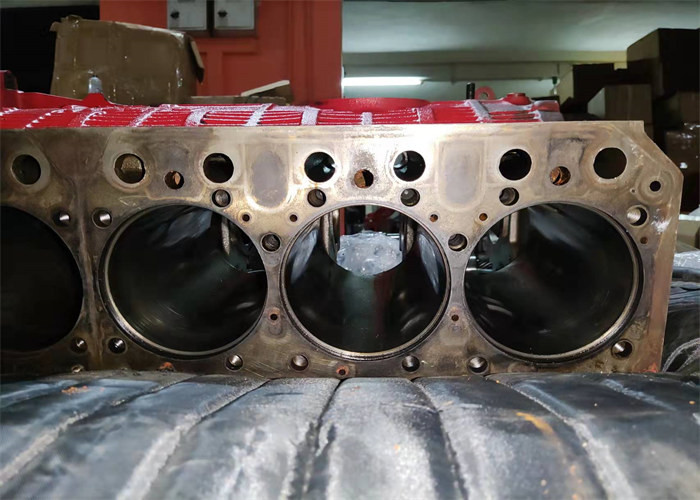

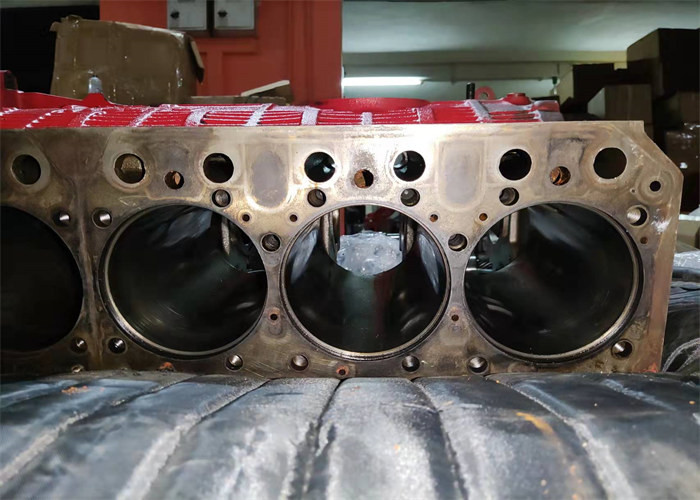

Cast-in cylinder liners

Specific types of cylinder liners (e.g. grey cast iron cylinder

liners) can also be considered as cast-in inserts. Again, an

insufficient wear resistance, but also not suitable tribological

characteristics are the main driving forces to introduce cylinder

liners into the bores of the aluminium engine block.